drawing two wires from 2.5-3.5mm to 2*1.0~1.8mm, 2*0.68~1.2mm,0.4~1.0mm

Double Intermediate Wires Drawing Machine

| Machine Type | JCJX-9DH-2 | JCJX-13DH-2 | JCJX-17DH-2 | |

| Drawing Wire No. | 2 Wires | |||

| Inlet Dia.(mm) | φ2.5~φ3.5 | |||

| Outlet Dia. (mm) | 2*φ1.0~φ1.8 | 2*φ0.68~φ1.2 | φ0.4~φ1.0 | |

| 1 * 2.8 Max. | 1 * 2.8 Max. | 1*2.0 Max. | ||

| Max. Die No. | 9 | 13 | 17 | |

| Max. Line Speed (m/min) | 1200 | 2000 | 2000 | |

| Body Structure | Ironed Cast | |||

| Drawing Capstan | Tungsten Plasma Capstan | |||

| Main Motor Power (kw) | 75 | |||

| Take-up Motor (kw) | 15 | |||

| Capstan Dia.(Max.)(mm) | φ300 | φ280 | φ250 | |

| Fix Speed Capstan Dia.(mm) | φ300 | φ280 | φ250 | |

| Transmission Type | By Gear | |||

| Lubrication Type | Full Immersion | |||

| Tension Control | Air Pressure Type | |||

| Take-up Type | Shaftless Type | |||

| Take-up Bobbin Size (mm) | φ500 ( Aperture φ127) | |||

| φ630 ( Aperture φ127) | ||||

| Traversing Type | Motor Type | |||

| Brake | Disc Brake | |||

| On-line Continuous Annealing Device | ||||

| Type | 350T-2 | 250TB-2 | ||

| Annealing Structure | Horizontal | Vertical | ||

| Annealing Wire Dia.(mm) | 2 * φ0.8~1.8 | 2 * φ0.4~1.2 | ||

| 1 *φ2.8 Max. | 1 * φ2.0 Max. | |||

| Annealing Voltage ( V ) | 0 ~ 60 | 0 ~ 60 | ||

| Annealing Current ( A ) | 0~4000A | 0~3000A | ||

Feature:

Space saving 50%

Electric saving 10%

Quick die change system for saving dies quantity 30%.

High production efficiency for 2 wires

Delivery time: 90 working days

Our Certification:

About us:

1.We established in 1990.We are the professional manufacturer have more than 30 years of experience in making all kinds of wire and cable machinery,realize the wire from drawing to extruding.

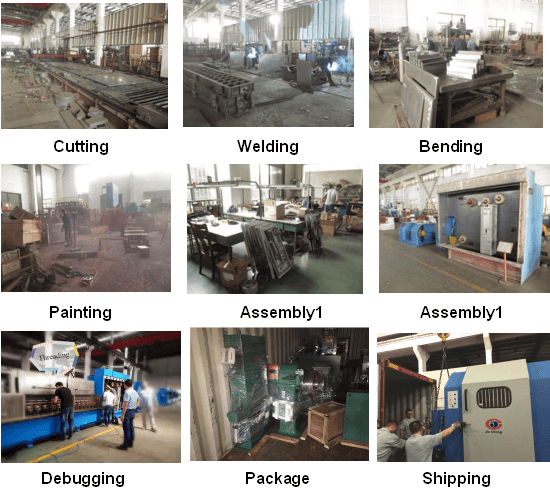

2.We are the factory not the trade company,Machine's body and other key components and parts are produced by our own factory,quality is reliable.

3.We can control the price the quality and the delivery time.