drawing copper rod form 8mm to 2.3-3.5 mm ,1.2-3.2mm,1.6-3.2mm,2.6-3.2mm with annealing

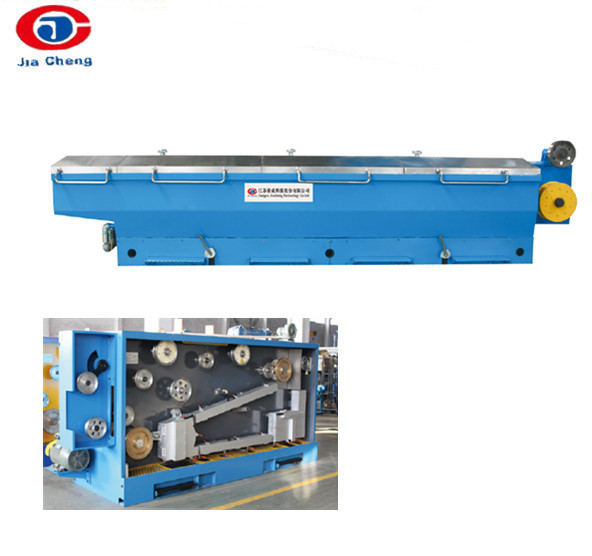

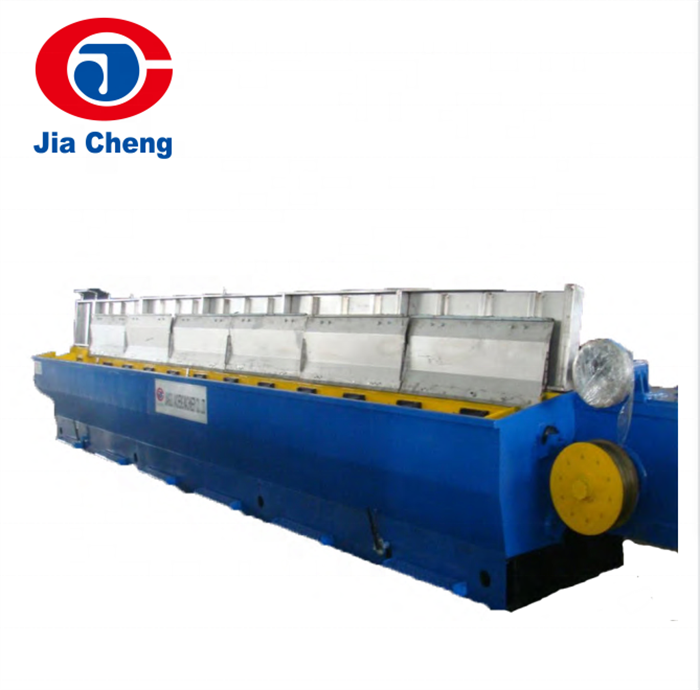

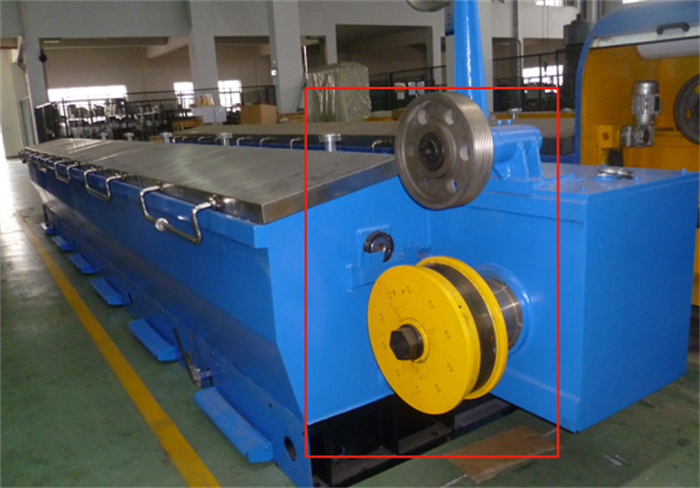

JCJX-LHT400 Copper rod breakdown machine

Usage: It's used for drawing and annealing Copper rod

Technical parameter:

Machine type | LHT400/13 | LHT400/11 | LHT400/9 | LHT400/8 | ||

Power control | Double inverter control | |||||

Inlet Dia.(mm) | 8 | |||||

Outlet Dia.(mm) | 1.2~3.2 | 1.7~3.2 | 2.3~3.2 | 2.6~3.2 | ||

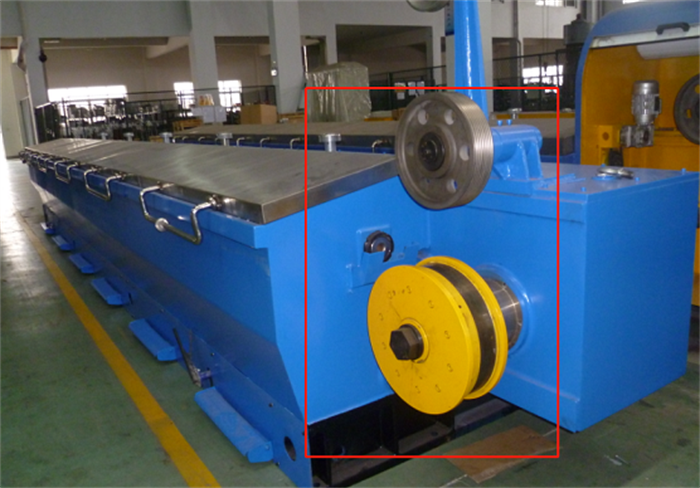

Drawing Drum Dia.(mm) | 400 | |||||

Fix speed capstan Dia.(mm) | 400 | |||||

Max.Die No. | 13 | 11 | 9 | 8 | ||

Drawing Speed(Max.)(m/s) | 15 | 12 | 12 | 11 | ||

Main Motor (KW) | 160(AC/DC) | 132(AC/DC) | ||||

Drum arrangement | Horizontal type | |||||

Drawing drum | Coated by tungsten | |||||

Drum lubrication type | Immersed type | |||||

Gear,bearing lubrication | By special pump,spray type | |||||

Online Continuous Annealer | ||||||

Machine structure | Horizontal type | |||||

Annealing wheel dia,(mm) | 350 | |||||

Max annealing voltage(V) | 65V(DC) | 60V(DC) | ||||

Max annealing current(A) | 4500 | 4000 | ||||

Take-up type(optional) | Double Take-up/Single Take-up/Colier | |||||

Optional equipment | Horizontal continuous annealer online | |||||

Optional function | Fast change die | |||||

Main feature:

1.Iron cast

2.High precision gear transmission, high efficiency , low noise.

3.Fully immersed way to lubricate and cool, which can guarantee the quality of drawing wire.

4.Annealing device is inclined, which is convenient for workers to cross wire. Special designed air pipe to send air to the axis of annealing wheel.

Delivery time: 90 working days

Our Certification:

About us:

1.We established in 1990.We are the professional manufacturer have more than 30 years of experience in making all kinds of wire and cable machinery,realize the wire from drawing to extruding.

2.We are the factory not the trade company,Machine's body and other key components and parts are produced by our own factory,quality is reliable.

3.We can control the price the quality and the delivery time.