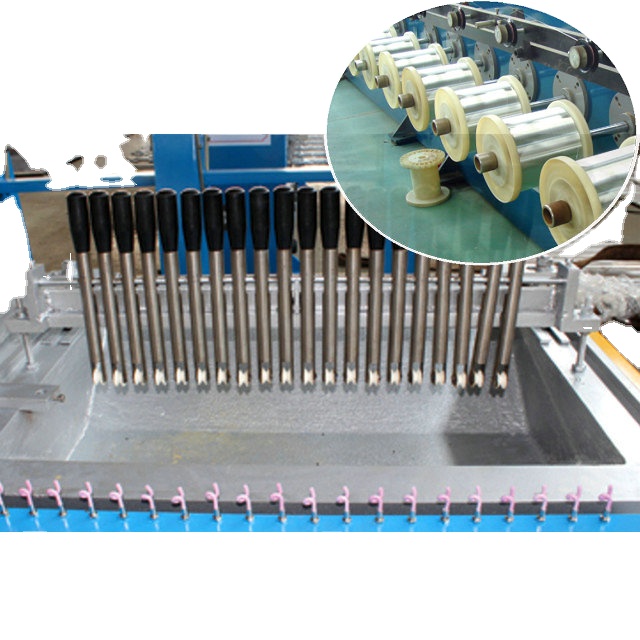

1. It is used to annealing and tinning copper wire from 0.1mm-0.7mm. 2. Add one room inside the annealer, can make the temperature impartial distribution. 3.Dual tinning tank design, it can produce two kind of tin-coating copper wire in the same time. 4.Spooler arranged in double layer can save space. 5.It is energy-saving(good heat preservation effect) and high efficiency(low maintenance rate).

Offline Wire Annealing and Tin-coating Machine

Usage:

This kind of machine is special for annealing and tinning 40 copper wires, CCA wire, Al-mg wire at the same time.

Technical parameter:

| Machine type | JCJX-32H/3.5 | JCJX-40H/4.5 | JCJX-40H/6 | JCJX-40H/7.5 |

| NO. of wire | 32 | 40 | 40 | 40 |

| Wire Dia. (mm) | Φ0.03~Φ0.08 | Φ0.08~Φ0.32 | Φ0.10~Φ0.65 | Φ0.1~Φ0.7 |

| Pay-off stand | Brush | Brush or overhead | ||

| Max. speed(m/min) | 300 | |||

| Annealing type | Radiation heating | |||

| Tinning type | Hot coating | |||

| Pay-off Bobbin Size(mm) | Φ250 | Φ300 | ||

| Take-up type | spooler drive by torque motor | |||

| Traverse type | Motor + inverter control | |||

| Take-up bobbin size | 4″~5″ | 5″~8″ | 5″~10″ | 5″~10″ |

| total power(KW) | 50 | 50 | 65 | 75 |

Main feature:

1.Dual tinning tank design

2.Can produce 2 kinds of tin-coated copper wires

3.Spooler arranged in double layers, saves space

Delivery time: 90 working days

Our Certification:

About us:

1.We established in 1990.We are the professional manufacturer have more than 30 years of experience in making all kinds of wire and cable machinery,realize the wire from drawing to extruding.

2.We are the factory not the trade company,Machine's body and other key components and parts are produced by our own factory,quality is reliable.

3.We can control the price the quality and the delivery time.